Equipment Rental

Equipment Rental Services

- Batch Mixer

- Centrifugal Pump

- Liquid Nitrogen Unit

- Wireline Unit

- Coiled Tubing Reel

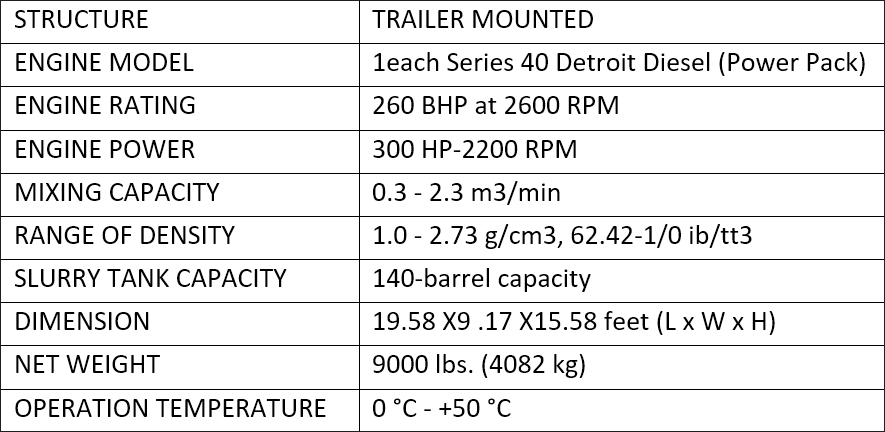

BASIC Trailer- Mounted Batch Mixer, consist of engine, transfer case, batch tank, mixing system, hydraulic system, electrical control system etc. This unit is used to mix slurry and send the mixed slurry to the pump unit continuously when carry out cementing construction.

The engine for the BASIC Batch Mixer is a Caterpillar 3406 electronic wet exhaust engine, 425 Bhp (317 KW).The engine is connected by a manual drive line and clutch assembly to Harrisburg 6X8 centrifugal pump designed to recirculate the complete volume of the mixing tank to a very high rate. The 4″ figure 206 hammer union on the inlet is connected to a vortex on the discharge of the pump. This is designed to allow materials to be moved to the unit by air or pump and uniform

The unit is mounted with a detachable hopper to mix dry or liquid chemicals. Engine shall always be air started. Engine includes air compressor and air reservoir. Unit includes an integrally mounted 132- gallon fueltank and includes spark arrestor and stainless-steel exhaust manifold. Diesel engine option is rated for safe area. No option is available for a Zone 2 dieselengine package

The batch tank centrifugal pumps are hydraulically driven by the auxiliary engine. Air to oil heat exchanger is also powered by a hydraulic motor.

The centrifugal pump is a BASIC 6X8 centrifugal pump for recirculation and boosting. The lifting frame includes integral lift and protective frame with permanently attached stainless steel drip pan. Handrails are included above the lift frame to address fall protection. Handrails can be folded to the inside to allow for lower overall height during shipping.

GENERAL PARAMETERS

PORTABLE CENTRIFUGAL PUMP SKID-CORROSIVE

Overview

The water supply skid can be used as auxiliary facility of cementing job individually, or supply recirculating power to water mixing tank. It can be classified to electrical driven and engine driven.

Main applications

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery.

Centrifugal pumps are used to induce flow or raise a liquid from a low level to a high level. These pumps work on a very simple mechanism. A centrifugal pump converts rotational energy, often from a motor, to energy in a moving fluid. … While passing through the impeller, the fluid is gaining both velocity and pressure.

Centrifugal Pump Application Types

1-Water Supply C.Pump:

Used for water supply to displacement tank and used as spare pump for injection pump. Equipped with ball valve at lower level of casing.

General Specification

MISSION MAGNUM PUMP [CORROSIVE]-SAND MASTER

2- Injection C. Pump:

Used for providing mixing energy for the mixing system. Add two 1 ” connector s on the discharge manifold of the centrifugal pump and the ball valve control switch to connect 1″ x20m cleaning hose. Equipped with drainage ball valve at the lower level of casing

3- Circulating C. Pump:

Used for circulating the slurry to slurry mixing tank through mixer, then the cement slurry can continuously mixing in the mixer. If one of the circulating centrifugal pump and the booster centrifugal pump fails, another pump can replace its work and complete the circulating mud and pumping mud. Equipped with drainage ball valve at the lower level of casing

4- Centrifugal. Pump:

Used for pump the slurry to plunger pump. If one of the circulating centrifugal pump and the booster centrifugal pump fails, another pump can replace its work and complete the circulating mud and pumping mud. Equipped with drainage ball valve at the lower level of casing.

PORTABLE CENTRIFUGAL PUMP SKID – NON-CORROSIVE

Overview

The water supply skid can be used as auxiliary facility of cementing job individually, or supply recirculating power to water mixing tank. It can be classified to electrical driven and engine driven.

Main applications

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery.

Centrifugal pumps are used to induce flow or raise a liquid from a low level to a high level. These pumps work on a very simple mechanism. A centrifugal pump converts rotational energy, often from a motor, to energy in a moving fluid. … While passing through the impeller, the fluid is gaining both velocity and pressure.

Centrifugal Pump Application Types

General Specification

MISSION MAGNUM PUMP [CORROSIVE]-SAND MASTER

1-Water Supply C.Pump:

Used for water supply to displacement tank and used as spare pump for injection pump. Equipped with ball valve at lower level of casing.

2- Injection C. Pump:

Used for providing mixing energy for the mixing system. Add two 1 ” connector s on the discharge manifold of the centrifugal pump and the ball valve control switch to connect 1″ x20m cleaning hose. Equipped with drainage ball valve at the lower level of casing.

3- Circulating C. Pump:

Used for circulating the slurry to slurry mixing tank through mixer, then the cement slurry can continuously mixing in the mixer. If one of the circulating centrifugal pump and the booster centrifugal pump fails, another pump can replace its work and complete the circulating mud and pumping mud. Equipped with drainage ball valve at the lower level of casing.

4- Centrifugal. Pump:

Used for pump the slurry to plunger pump. If one of the circulating centrifugal pump and the booster centrifugal pump fails, another pump can replace its work and complete the circulating mud and pumping mud. Equipped with drainage ball valve at the lower level of casing

The open framed 180K Liquid Nitrogen pumping and vaporizing system has the following identifications:

A skid mounted liquid nitrogen pumping and vaporizing system, complete as described in the Scope of supply.

Wireline services refer to a cabling technology that a wireline service provider in oil and gas exploration and production and Water well business can provide to perform functions like intervening, pipe recovery and reservoir evaluation, etc

This unit has 52”Split Drum Tandem Axle heavy duty logging Van with 5/16” mono conductor 260C and 15/32 7 conductor 260C Cable 15K

This unit equipped with Warrior Single conductor tool interface panel with well logging software.

HYDRA RIG 24K TM Coiled Tubing Reel with below capacity,

• 1.25” Length 51,400 FT

• 1.5” – Length 34100 FT

• 1.75 – Length 24400 FT

• 2.00” – Length 19500 FT

• 2.38” – Length 12700 FT

Dimension

• Core dia 76” Flange dia 156”, inside flange width 69”

• Swivel size 2”-15K counter from 1.5”-2” fit for 24K

• Reel speed @ 28GPM 2500PSIG

• Level wind override & Level wind lift circuit

• Direct Drive Gear box motor allows for a max drive torque of 24K ft-lbs

• Hybrid Planetary motor allows port for collector port for Wireline on drive side

Call us for a First class Rentals and Services Partner

Headquarters

We Are Everywhere